Space has no limits. And neither should your business.

Space Industries offers full-scale AIT services for satellite manufacturers and OEMs. With one of Europe’s largest Clean Rooms and a production model built on automotive-grade efficiency, we turn your satellite into flight-ready hardware—on time and on budget.

Who you are

Structured Space Company

You are an established company in the space sector, but you need additional space. Or simply a better space to safely integrate, assemble, and test your satellites, up to 700 kg.

Fab-less Space Company

You are a startup or a company that specializes in engineering. You are ready to make the best space technology in history but you don’t have a place to do it in efficiency, security and privacy.

Design for Production

In the space industry, design often begins with ambition and ends with complexity.

At Space Industries, we bridge the gap between design and production, helping aerospace OEMs transform their satellite concepts into scalable, manufacturable systems.

We work alongside engineering teams during the design phase to ensure every choice, from structural, thermal, electrical, to system-level, responds to industrial logics from the very start.

This approach allows satellites to move seamlessly from prototype to serial production, reducing time, cost, and risk while maximizing performance and reliability.

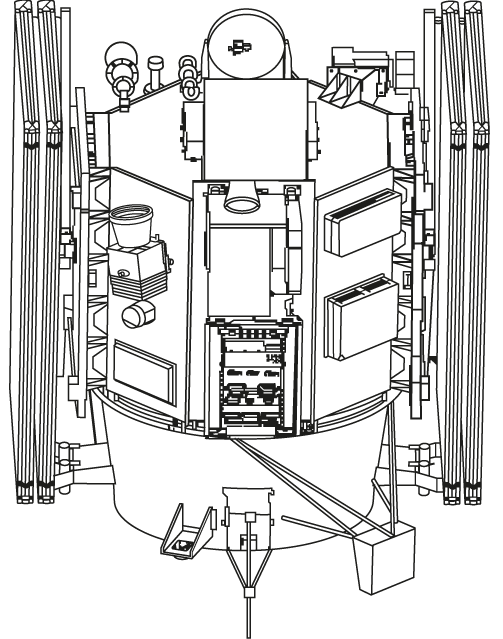

We design for reliability and orbital performance.From structural and thermal behavior to power balance and payload integration, every choice is driven by the mission’s real needs. Our engineers work to ensure that each subsystem performs at its best while keeping the satellite optimized for industrial production.

We design for scalability and precision.

By reducing unique parts, standardizing interfaces, and applying modular architectures, we make satellites faster to assemble, easier to test, and ready for series production. This is where design meets the efficiency of our Stellar Hub and its single-facility AIT process.

We design for sustainability and growth.

Integrating economic analysis throughout the design phase allows us to control materials, processes, and timelines. The result is a satellite that performs at the state of the art, while being predictable, cost-effective, and ready to scale.

Precision, repeatability, peformance

In traditional satellites, electrical harnessing represents one of the most complex and time-consuming phases of production. Dozens of cables, connectors and interfaces must be manually assembled, tested and routed within confined volumes, a process that can take weeks and offers limited opportunities for standardization or scalability.

At Space Industries, we are developing the application of Flat Flex Cabling (FFC) technology to Space, proven in demanding aerospace and automotive sectors, to optimize satellite integration for serial manufacturing.

Unlike conventional round-wire harnesses, FFC employs flat, lightweight, digitally designed flexible circuits that can be precisely engineered to match spacecraft structural requirements.

This approach enables a more systematic wiring architecture, designed for automated and repeatable manufacturing processes.

By integrating FFC considerations into the early satellite design phase, we aim to significantly reduce wiring complexity and minimize manual routing requirements. Every connection can be pre-engineered, pre-tested, and manufactured with consistent precision, substantially reducing integration and testing timelines.

The flat geometry of FFC technology offers inherent advantages in packaging efficiency and controlled impedance characteristics, while enabling notable mass optimization compared to traditional harness solutions — a critical factor for launch cost efficiency.

Our FFC approach represents a step toward true Design for Manufacturing in the satellite industry. Currently under qualification for space environments, this technology pathway could enable satellites to be built with greater consistency and speed, supporting the transition from traditional handcrafted processes toward scalable industrial production.

Solutions

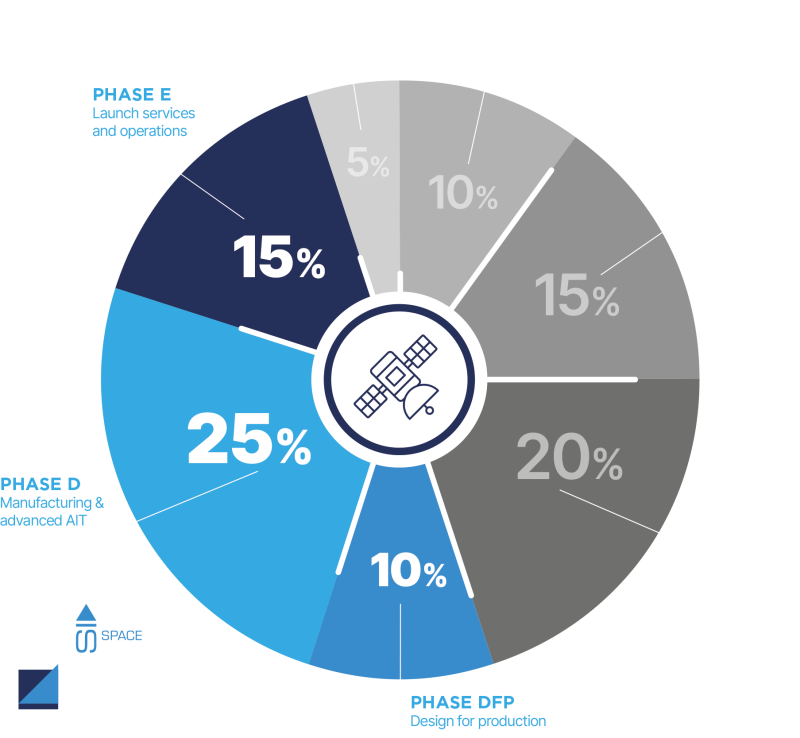

The aerospace market is divided into stages A through F.

SpaceIndustries (SI), with a focus on stages D and E, is able to provide end-to-end services through its partner network, ensuring high-quality solutions along the entire value chain.

ACCEPTANCE

From components to complianceEvery unit entering our facility undergoes rigorous acceptance procedures to guarantee conformity with space standards. We perform complete documentation checks, visual inspections, and interface verifications to ensure hardware reliability from day one. By applying aerospace-grade protocols combined with industrial discipline, we secure a flawless starting point for your satellite.

ASSEMBLY

Precision built into every structureEach box maintains the highest level of privacy, with dedicated access and controlled airflow. Offering clients a secure, exclusive environment for their satellite. The modular design supports quick reconfiguration and expansion, preserving operational efficiency while ensuring that customer needs are met with agility and confidentiality.

INTEGRATION

Seamless systems, zero compromiseBeyond technical operations, these clean rooms are designed to be personalized for communications: storytelling, demonstrations, media events, all within a controlled, visible, and secure setting. The “satellite stables” concept ensures the environment supports both high-precision integration tasks and engaging client experiences, embodying versatility and precision in every module.

TESTING

Where performance meets proofFrom thermal vacuum to vibration, from EMC to leak tests, every satellite is validated in-house under the most demanding conditions. Continuous monitoring and full traceability ensure that no parameter is left unchecked. Having all AIT capabilities under one roof reduces lead time, eliminates transport risks, and delivers satellites that meet ( and exceed) mission-critical requirements.

QUALITY ASSURANCE

Certainty in every detailQuality is not a final step, it is embedded in every phase of our AIT process. We operate under strict compliance with international aerospace standards, ensuring full traceability of components, procedures, and results. From incoming inspection to final acceptance, every action is documented and validated, providing OEMs with the confidence that their mission is backed by uncompromising quality.

CUSTOMER EXPERIENCE

Your mission, your spaceAt Space Industries, we go beyond technical excellence by creating a working environment tailored to our clients’ needs. OEM teams are welcomed into secure, dedicated spaces - private clean room boxes, meeting rooms, and offices - allowing them to manage integration as if they were in their own facility. This approach fosters collaboration, preserves confidentiality, and turns our plant into a seamless extension of your operations.

PRIVACY AND SECURITY

At Space Industries, we don’t compete with your satellite platform: we empower it. Our facilities are optimized for industrial satellite production, offering a scalable and reliable environment for integration, assembly, and testing of satellites up to 700 kg. Whether you’re an established OEM or a fast-scaling space startup, our mission is to make yours fly—efficiently, accurately, and with total confidentiality.

By the customer's side at all times

Missing a critical component for your satellite project?

Space Industries leverages its global network to connect you with the right partners, ensuring your project stays on track.

Are there any restrictions for space tours?

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam.

What’s the cancellation policy?

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam.