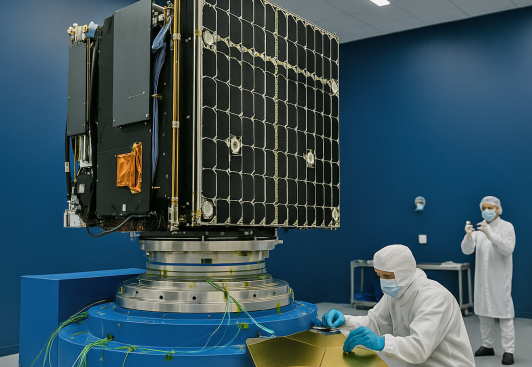

Shaping the industrial future of satellites

The space market is entering a new era. Satellites are no longer unique prototypes but strategic assets that must be produced with the same reliability, scalability, and efficiency as any advanced industrial system. They are becoming commodities.

At Space Industries, we are building the factory model of tomorrow. Where satellites are assembled, integrated, and tested with automotive-inspired processes, modular facilities, and uncompromising quality standards.

Our vision is clear: to make satellite manufacturing faster, more repeatable, and more accessible, enabling OEMs to focus on innovation while relying on us for flawless execution.

01

INDUSTRIAL-SCALE PRODUCTION

Serial manufacturing of satellites up to 700 kg, with processes inspired by the automotive industry to ensure speed, repeatability, and cost efficiency.

02

MODULAR CLEAN ROOMS

Over than 2,500 sqm of ISO 8 clean rooms, designed as adaptable “satellite stables.” Each customer can work in a private, dedicated box with maximum flexibility and confidentiality.

03

ALL-IN-ONE PRODUCTION FACILITY

From assembly to testing, everything happens under one roof. This eliminates transport risks, reduces lead times, and secures full quality control.

04

PROVEN EXPERTISE & SOLID FOUNDATIONS

Backed by the industrial strength of Comat SpA and led by international aerospace experience, Space Industries combines reliability with bold vision.

Our plan at-a-glance

The Future’s just around the corner

40 satellites in parallel by 2030

Through space and process optimizations, Space Industries will achieve a production capacity of up to 40 satellites in parallel, with a maximum production time of 100 days per single satellite.

By 2030, Space Industries will be able to make an average of one satellite per working day.